Optics and Telescope Makers

Production challenges

In all modern production situations, time is a precious resource. In optics manufacturing, metrology has historically been a cause of delay, in that glass in production would need to be removed from production, or at best, production needed to be paused for interrim measurements to be made.

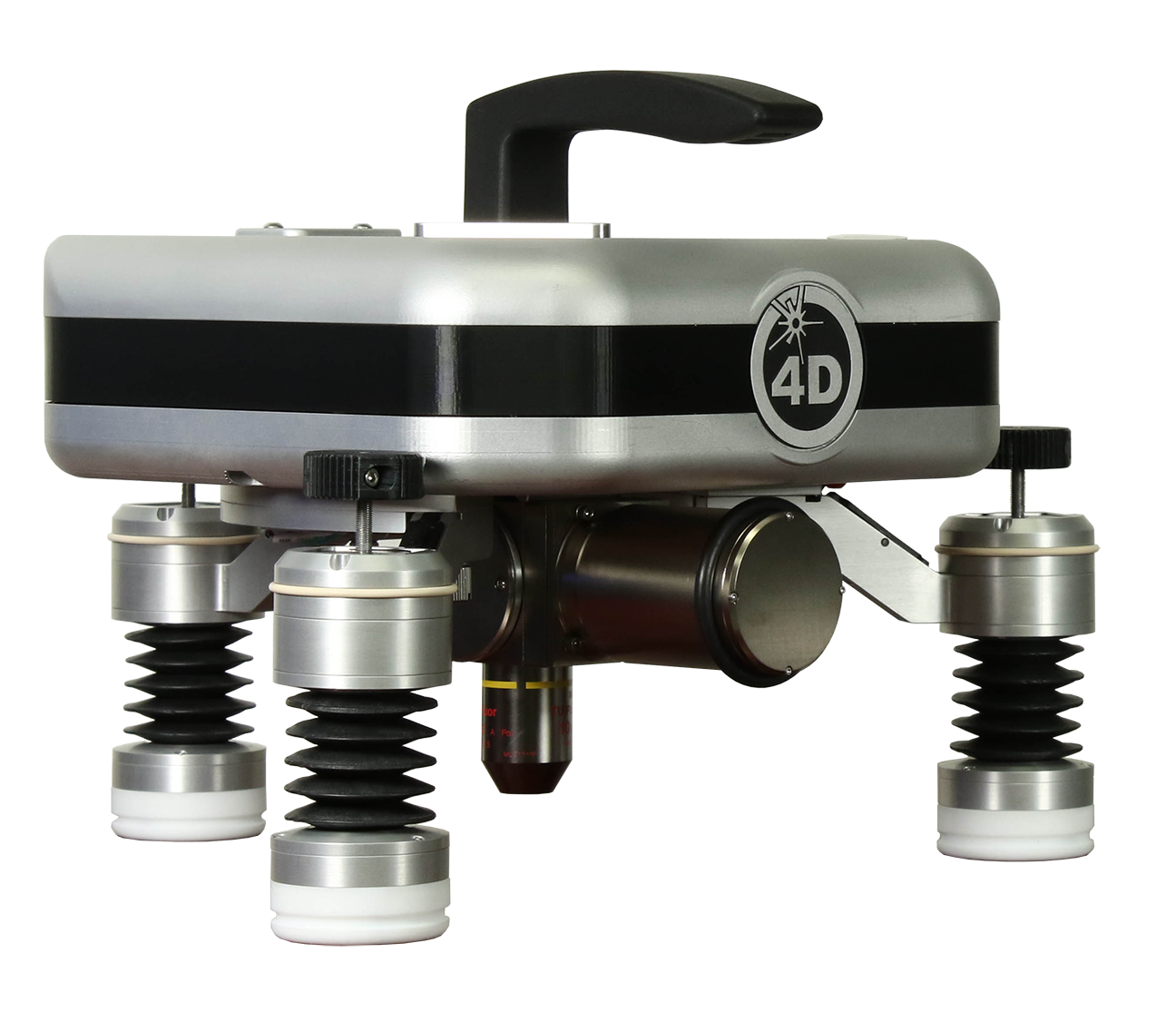

With 4D Technology’s fast, vibration immune measurement technology, precision glass manufacturers can measure in situ, on the polishing machine, as shown in the picture below.

Large, Monolithic Mirrors

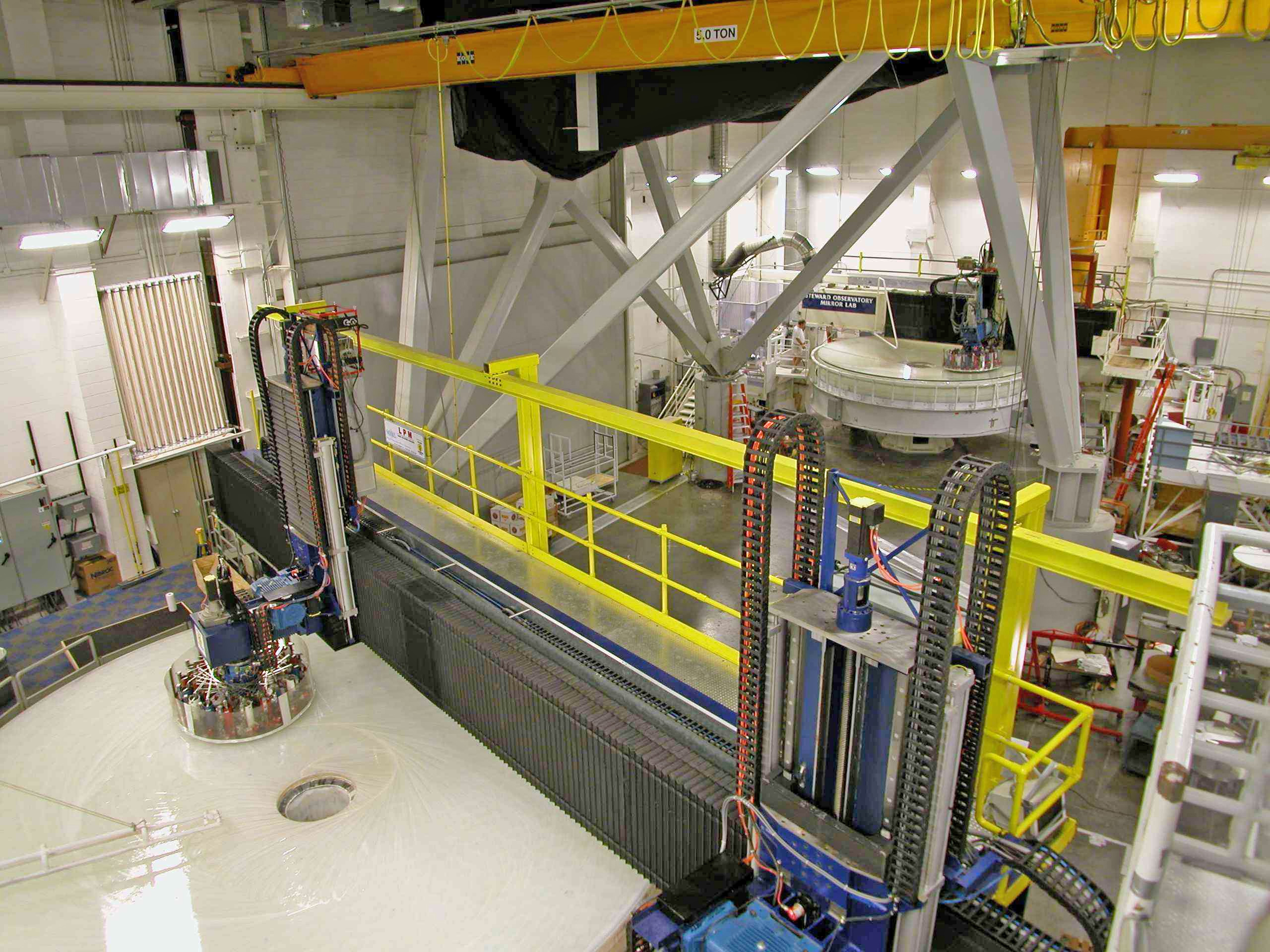

Large surfaces, whether the monolithic glass blanks produced at world-leading mirror labs—such as the one at the University of Arizona’s Richard F. Caris Mirror Lab—or large multi-mirror arrays have obvious challenges in reducing vibration in the system to low enough levels to get good measurements.

Fortunately, our dynamic interferometers are light, and small, and fast. Some manufacturers mount these instruments in towers or on gantrys above the production floor—gaining a lookdown measurement with ease.

Polish and surface finish

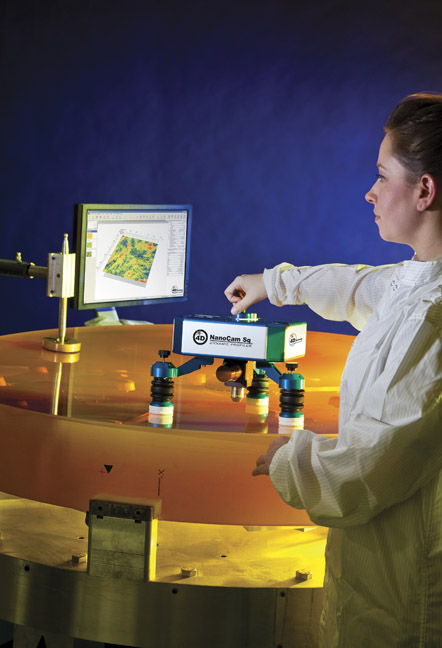

Checking polish on large optics is difficult using ordinary profilometry, because their sample stages are limited in weight and dimensions. NanoCam measures nanometer scale variations in height. It is portable and safe to place on an optical surface, nor does it need vibration isolation.

Added Technical Resources

Measurement of Space Optics and Structures

This paper presents an overview of the techniques and configurations used to build dynamic interferometers and measurement results for a variety of space-based optical components.

Vibrational Characteristics of Light-weight Mirrors

We present a technique to characterize and quantitatively measure the vibrational mode shapes and amplitudes of mirrors concurrently with surface figure testing..

Measuring Sub-Angstrom Roughness

How do you measure roughness with sub-angstrom precision in a noisy manufacting environment?

Read this white paper for a break-down of the options, and illustrations of the challenges presented by different solutions.

Products for Optics and Telescope Manufacturing

PhaseCam IR Interferometers

Compact, lightweight and vibration-insensitive for accurate surface and wavefront measurements at infrared (1.064 through 3.39 micron) wavelengths.

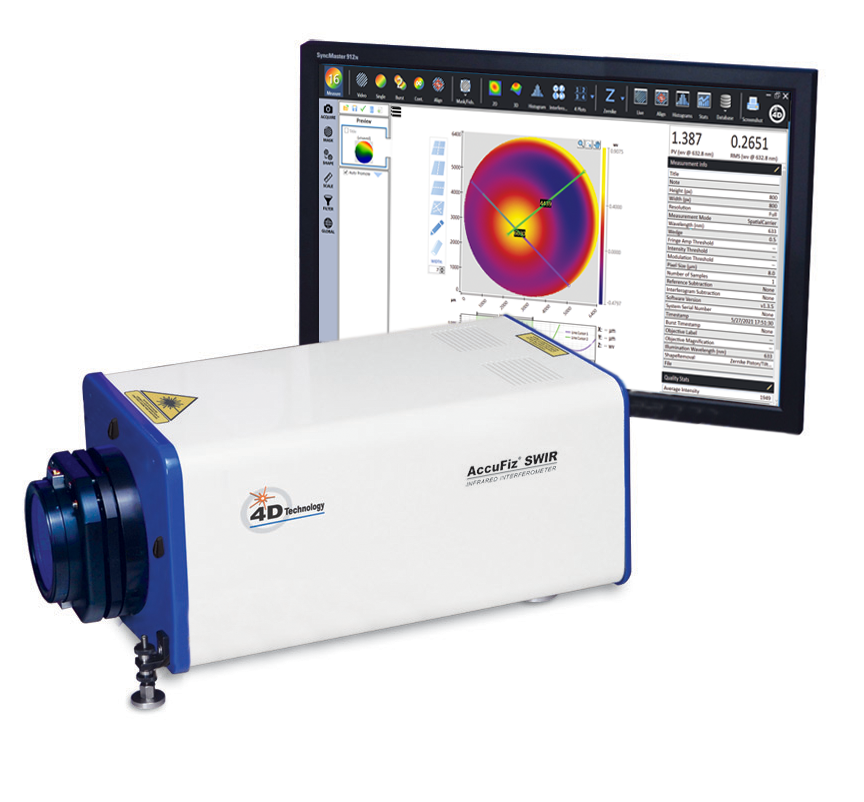

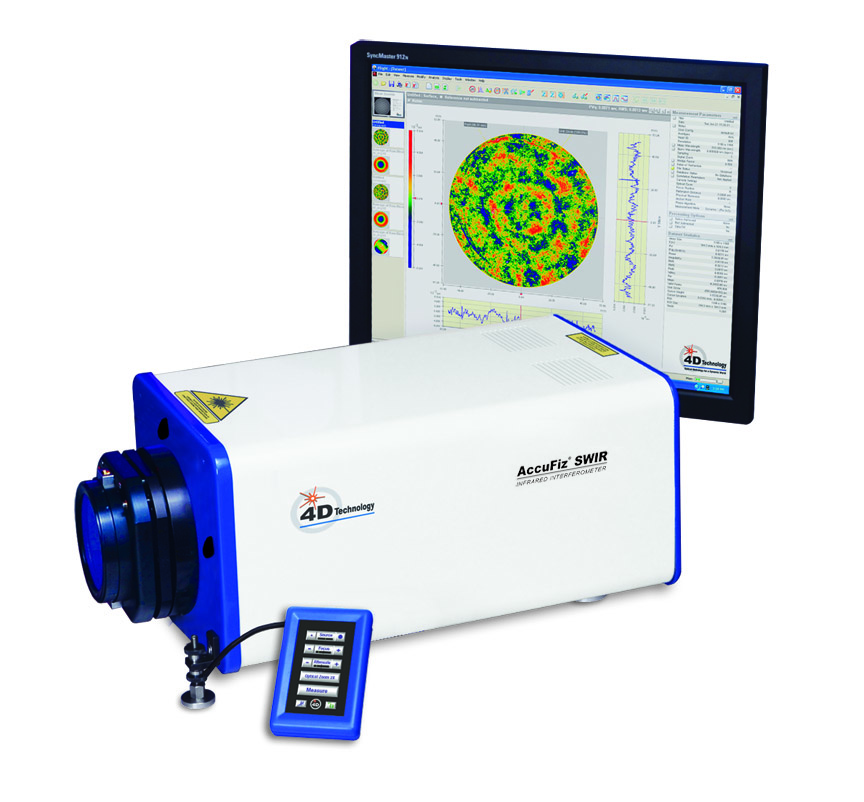

AccuFiz IR Fizeau Interferometers

Consistently high performance, quality and value for accurate, repeatable measurement at infrared wavelengths.

AccuFiz

Excels at fast, repeatable measurement of surface shape and transmitted wavefront error of flat and wedged optics. It is the most versatile Fizeau available, for any production environment.

Optical Profilers

NanoCam HD systems measure surface roughness on coated and uncoated precision surfaces to ensure the quality of polishing processes.

Do you need custom-built metrology?

Get a free consultation. 4D Technology’s mechanical, optical, electrical and software engineering teams are standing by to evaluate what it would take to meet your application’s requirements.

Get In Touch

(520) 294-5600

Location

3280 E Hemisphere Loop, Ste 146

Tucson, AZ 85706

4Dinfo@ontoinnovation.com

Office Hours (Arizona Time)

Mon: 8am - 5pm

Tue: 8am - 5pm

Wed: 8am - 5pm

Thur: 8am - 5pm

Fri: 8am - 5pm

Sat: Closed

Sun: Closed